The Young Business division of DS Group develops innovative solutions for a sustainable and secure future. One example is Lynatox GmbH, a subsidiary based in Luisenthal, Germany. The company specializes in the residue-free removal of organic pollutants from air and water. Its patented photocatalysis technology operates without chemical additives, biocides, ozone, or conventional filter systems. Instead, organic compounds are broken down at the nanoscale into water, CO₂, and mineral salts.

Deployment at Regis-Breitingen Secondary School

In 2025, elevated levels of naphthalene – a substance classified as potentially carcinogenic – were detected in several rooms at Regis Breitingen Secondary School (District of Leipzig). Parts of the building had to be closed as a precaution.

Following expert consultation, the municipality acted swiftly and decided to install Lynatox systems in 18 rooms. The objective was clear: to ensure that regular school operations could safely resume in full after the summer holidays.

The installed units remove naphthalene as well as other organic pollutants, mold spores, bacteria, and viruses directly from indoor air. Initial feedback from the school indicated a noticeable improvement in air quality within a short period of time. The technology provides the municipality with a reliable interim solution until structural remediation measures are completed.

The deployment in Regis-Breitingen demonstrates the potential of modern air purification technology. We can make buildings that were once considered problematic safe to use again. Our vision is to develop technical solutions that support and accelerate remediation processes while conserving resources.

Daniel Martschoke, Founder and Managing Director, Lynatox GmbH

How Lynatox Photocatalysis Works

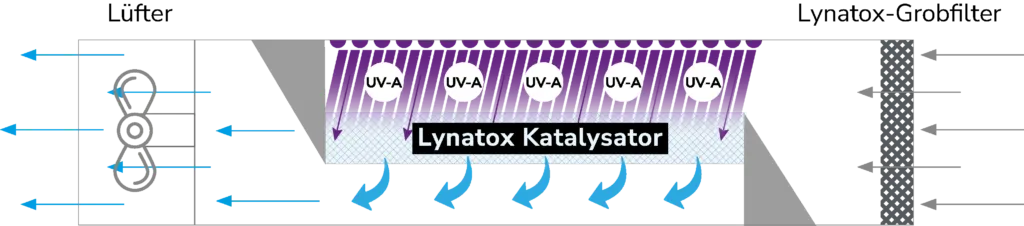

First, air passes through a coarse dust pre-filter before flowing through the catalyst, which is activated by UV-A light. The proprietary Lynatox coating absorbs organic pollutants and catalytically decomposes them directly on the surface. The purified air is then returned quietly and draft-free into the room. This approach fundamentally differs from conventional filter-based systems, which merely retain pollutants instead of eliminating them.

Contaminated air passes through a coarse dust filter and flows through the catalyst, which is simultaneously activated by UV-A light.

Advancing Sustainable Building Technology

With its photocatalysis technology, Lynatox makes a significant contribution to sustainable building systems. Because organic pollutants are fully decomposed, no secondary waste is generated. The UV-A LED modules used are highly durable and typically require replacement only after five to six years, ensuring resource-efficient and cost-effective operation.

The air purification units are manufactured in Germany and incorporate components supplied by local partners.

The project in Regis-Breitingen illustrates how Lynatox enables indoor spaces to become usable again quickly, safely, and efficiently—particularly in older buildings or situations where structural remediation requires time. For municipalities, businesses, and public institutions, the DS subsidiary opens up new opportunities to sustainably improve indoor air quality while acting in an environmentally responsible and resource-efficient manner.